Armstrong’s Inverted Bucket Steam Trap, invented in 1911, remains the top-performing steam trap. We offer a full range of steam traps, including inverted bucket, float & thermostatic, and thermodynamic models for various industrial applications.

Armstrong International

Armstrong International Pumps are engineered to provide efficient, reliable, and sustainable solutions for fluid flow management across various industries. Known for their innovative design and energy-efficient performance, these pumps are commonly used in HVAC, plumbing, and industrial applications.

Popular Pump Types:

- Circulator Pumps – Ideal for HVAC and hydronic systems.

- Boiler Feed Pumps – Designed for steam and hot water systems.

- Condensate Pumps – Efficiently handle condensate in steam systems.

- Pressure Boosting Pumps – Provide consistent water pressure across facilities.

Category

Need Help?

Steam Traps

Steam Tracing

Armstrong provides custom, pre-assembled packages, including steam distribution manifolds, Trap Valve Stations, steam traps, and protection valves. Our Steam Tracing Equipment offers benefits like faster installation, easier maintenance, improved safety, and increased energy savings.

Strainers

Armstrong offers a wide range of Y-type, T-type, and fabricated basket pipe strainers in various sizes and materials to suit most pipeline straining needs.

Condensate Solutions

Armstrong offers a full range of pumps for condensate recovery, including pump trap packages, steam trap/pump combinations, electric pump packages, boiler feed systems, and flash recovery vessels. These solutions cover all your condensate recovery needs efficiently.

Pressure & Temp Controls

Armstrong pressure and temperature control valves ensure safe and efficient management of steam, air, and liquid systems. They maintain consistent pressure or temperature for process control, ensuring uninterrupted productivity.

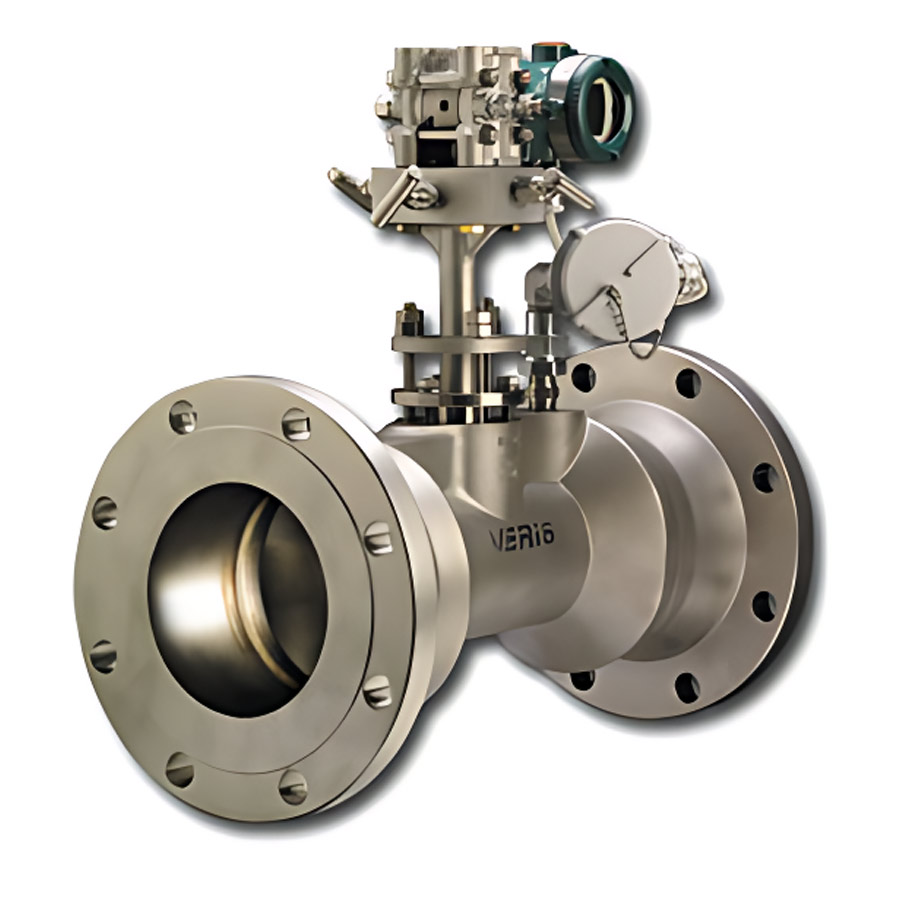

Flow Measurement

Accurate flow measurement is essential in various industrial and institutional settings. Armstrong’s VERIS Flow Measurement solutions offer advanced technology to meet these critical needs effectively.

Air Vents

Armstrong’s Float-Operated Air Vent Relief Traps remove gases from liquids with a specific gravity as low as 0.40. Thermostatic devices are also available for evacuating gases from steam systems.

Liquid Drainers

Armstrong’s Float-Operated Drain Traps efficiently drain heavy liquids from gases or light liquids. They operate up to 1800 psig / 255 barg and handle specific gravity as low as 0.40.

Humidification

Armstrong offers various humidification solutions for precise, trouble-free control across industries. Options include direct steam injection, fogging, electronic, evaporative media, gas, and steam-to-steam systems.

Hot Water Solutions

Armstrong provides innovative hot water generation and control solutions for institutional and industrial applications. We optimize performance and safety with water heaters, temperature controls, and hose stations.

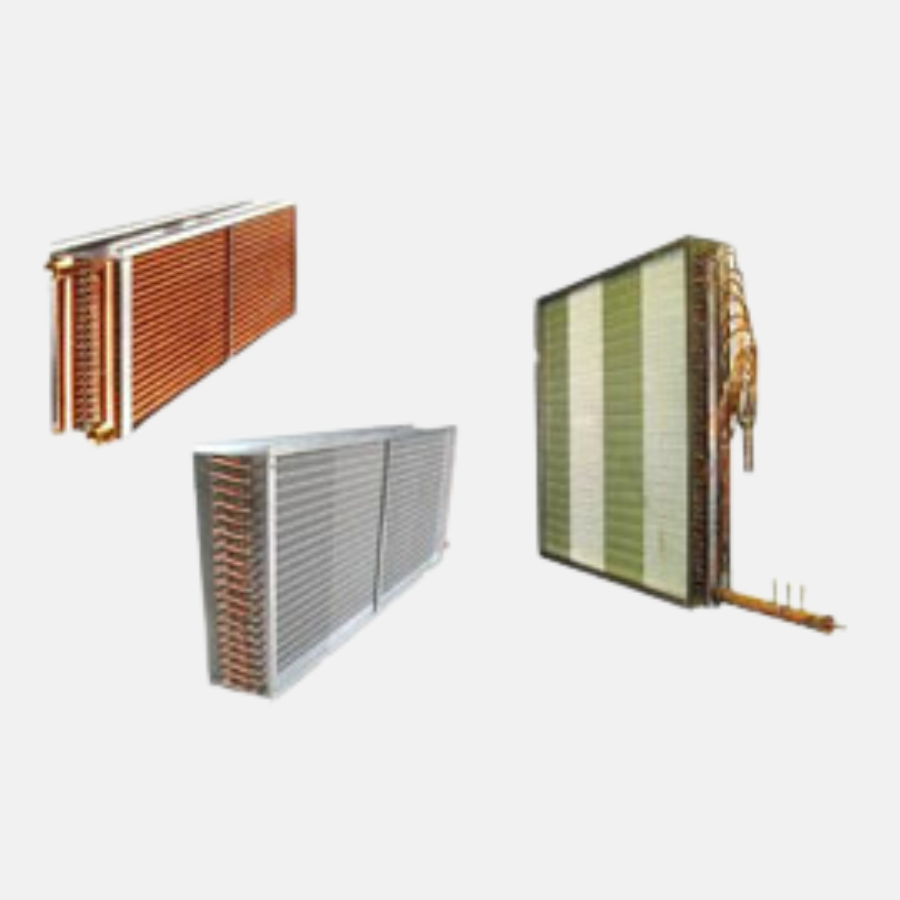

Heat Transfer Coils

Armstrong offers expert design and manufacturing of heat transfer coils for air and gas treatment. We provide steam/liquid and cooling coils in heavy-duty finned tube and lightweight plate fin configurations, tailored to your specific needs.

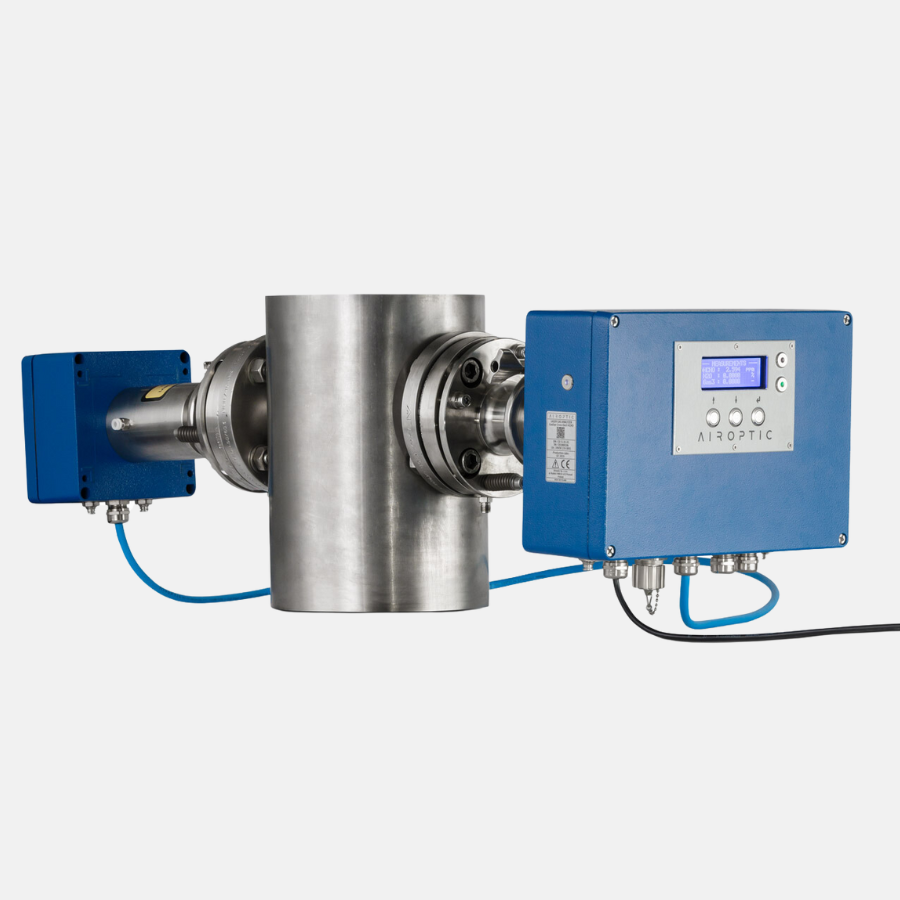

Steam Quality Monitoring

Armstrong’s Steam QM™ series offers automatic steam quality monitoring to enhance system efficiency and safety. It ensures steam quality meets global standards.

Energy Optimization Services

Armstrong provides comprehensive energy optimization services, including audits, O&M, project management, and training. We ensure timely, budget-friendly project completion with expert oversight and support.

Armstrong University

Armstrong University offers seminars, online training, and custom-tailored education, sharing over a century of thermal utility expertise. We help you optimize energy use with in-depth knowledge and solutions.

Expert Solutions for Industries

Armstrong’s experts deliver tailored solutions with deep knowledge across industries, ensuring quality, safety, and efficiency. We help reduce energy use and emissions in sectors like healthcare, food & beverage, power, and more.

Stay connected with us through our social media channels for the latest updates, project showcases, and construction tips.